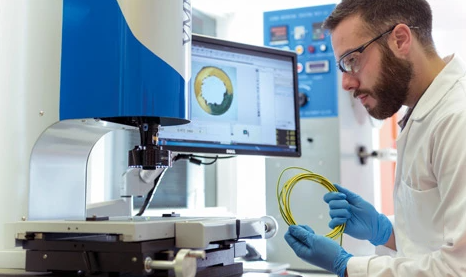

Our clients can expect high quality products to be produced at ZYMEI-KABEL with a good reason. To meet this claim 365 days a year ZYMEI-KABEL has its own physicochemical laboratory, a test centre and a large quality control department. In the material laboratory the raw materials and semi-finished parts for the cable production are tested to comply with the necessary quality and quantity parameters. At the same time

the laboratory forms the basis for the permanent new and further development of our products. Our test centre with extensive equipment is able to test the products according to the applicable technical directives and under practical application conditions in long-term tests. Mechanically high loaded cables are tested in the dragchain test stand (up to 35 m/s²) or in bending-torsion tests (up to 20 m cycles) for their suitability.

the laboratory forms the basis for the permanent new and further development of our products. Our test centre with extensive equipment is able to test the products according to the applicable technical directives and under practical application conditions in long-term tests. Mechanically high loaded cables are tested in the dragchain test stand (up to 35 m/s²) or in bending-torsion tests (up to 20 m cycles) for their suitability.

Comprehensive quality tests for cables

• Tensile and sheering strength test

• Resistance test

• Electrical test

• Torsion test

• Torsion-bending test

• Drag chain test

• Roll bending test

• Fire tests