Rated voltage:Uo/U 600/1000V

Test voltage:4000V

Insulation resistance at +20° C:≥:(+20°C):≧20MΩx km

Bending radius:

stationary :3 x cable diameterØ

flexible:7.5 x cable diameterØ

Temperature range:

flexible:-5°C - 90°C

stationary:-40°C - 90°C

Radiation resistance:≤80×10cJ/kg

Flame retardant:IEC 60332-1

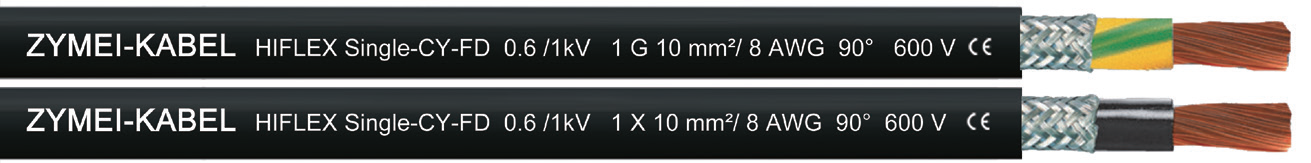

● Bare copper, extra fine wire conductors, to DIN VDE 0295 cl. 6, col. 4, BS 6360 cl. 6 and IEC 60228 cl. 6, however by 185 mm² up to 300 mm² with reduced single wire-ø, max. 0,30 mm

● 1. Core insulation of special PVC, TI3 to DIN VDE 0281 part 1 / DIN VDE 0281 part 3,colour black or green-yellow Tinned copper braided screening, coverage approx. 80%

● 2. Core insulation (jacket) of special PVC,YM5 to DIN VDE 0207 part 5

● colour orange (RAL 2003)

High flexible special single core screened cables for drag chains are used for flexible use for medium mechanical stresses with free movement without tensile stress or forced movements in dry, moist and wet rooms. These two-norm cables primarily designed for exportorientated machinery manufacturer for flexible applications in machineries, machine tools, robot technics, for movable automated machinery parts. These screened cables are particulary suitable for the interference-free transmission in instrumentation and control engineerin g applications (electromagnetic compatibility). For applications which go beyond standard solutions we recommend for our especially developed enquiry sheet for energy guiding systems. Before installation in cable trays please read the instructions. Further technical details see selection table for drag chain cables, see lead text.

| Part No. | No.cores Xcross-sec. mm² |

Outer Øca. mm |

Cop.weight kg / km |

Weight ca. kg / km |

|---|---|---|---|---|

| 306031 | 1G10 | 10,0 | 130,0 | 230,0 |

| 306032 | 1x10 | 10,0 | 130,0 | 230,0 |

| 306033 | 1G16 | 11,1 | 190,0 | 300,0 |

| 306034 | 1x16 | 11,1 | 190,0 | 300,0 |

| 306035 | 1G25 | 12,3 | 260,0 | 420,0 |

| 306036 | 1x25 | 12,3 | 260,0 | 420,0 |

| 306037 | 1G35 | 15,1 | 405,0 | 615,0 |

| 306038 | 1x35 | 15,1 | 405,0 | 615,0 |

| 306039 | 1G50 | 17,2 | 560,0 | 825,0 |

| 306040 | 1x50 | 17,2 | 560,0 | 825,0 |

| 306041 | 1G70 | 19,0 | 780,0 | 1090,0 |

| 306042 | 1x70 | 19,0 | 780,0 | 1090,0 |

| 306043 | 1G95 | 22,0 | 1030,0 | 1395,0 |

| 306044 | 1x95 | 22,0 | 1030,0 | 1395,0 |

| 306045 | 1G120 | 23,6 | 1285,0 | 1770,0 |

| 306046 | 1x120 | 23,6 | 1285,0 | 1770,0 |

| 306047 | 1G150 | 25,8 | 1570,0 | 1930,0 |

| 306048 | 1x150 | 25,8 | 1570,0 | 1930,0 |

| 306049 | 1G185 | 29,8 | 1940,0 | 2635,0 |

| 306050 | 1x185 | 29,8 | 1940,0 | 2635,0 |

| 306051 | 1G240 | 33,5 | 2530,0 | 3380,0 |

| 306052 | 1x240 | 33,5 | 2530,0 | 3380,0 |

| 306053 | 1G300 | 36,2 | 3140,0 | 4120,0 |

| 306054 | 1x300 | 36,2 | 3140,0 | 4120,0 |